A helmet's job is to protect not only your head but also the precious brain inside it. At Dirt Rider we are open to any product that can help prevent injury in the case of a crash. The new 6D helmet comes at the world of head protection differently than the rest and we recently got a first look at how the designers of the helmet are approaching the science of protecting riders grey matter. We'll be riding in this helmet before you know it and are excited to offer a full product test of its performance and function. In the meantime, you can find additional info at www.6dhelmets.com, and read on to learn more about this cool, new technology:

We need a softer, more compliant helmet design, but without compromising high-energy performance. —Bob Weber, Founder / CEO

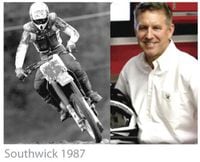

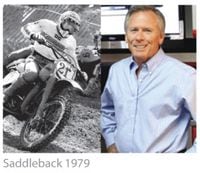

Two former professional motocrossers, Bob Weber (Founder/CEO and Innovator of the 6D helmet) and Robert Reisinger (Founder and Director of Engineering) have put their 60 combined years in the motocross industry to the challenge of creating what they feel is a safer helmet. It starts with Weber and Reisinger’s ODS system, which is short for Omni-Directional Suspension. Their system is a fully active, in-helmet suspension and kinetic energy management system. The mix of mechanics, engineering and different materials can sound confusing but the idea is rather simple, it’s suspension for your skull.

/cloudfront-us-east-1.images.arcpublishing.com/octane/HW5JR2M73FGVRKOMWR5V2UALXM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JV4YASHEPVELJNID4BLLKY4ZKQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/646LH2AYM5CI5OP56WCTRYBPGY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/FBUJSX2P4JE7XON6OUK4OQCYTY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/WOYUZXUAMBCZZJ3BQWOEQJGR5M.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/OBHVYZHWBBAZTALZA4GC5RM5WA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/ZJPPRO5CRNFYPEVMWIFR7RRFQQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/MMAOLEHZG5CBXAOICNKNGCEK4I.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/KQUVDTNB6VF53CRDNN47BE3VUA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/3T32INAZQRGPXOGGA36NQJDSSM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/EPLS5PBKXBHNXK7S5O7G4ND3YQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/MNGOZAGZFZBH5DPFV7NOPF5S3Y.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/VGJWIIFM2VBCXG34KRQ37GCP7U.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/2ZU3HXRPMZESJF7HDLZJV7FHEY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/VVFWQBZEIZDVJHZIW5ISKWKOZU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/7T7FZXHIIBDX7AOBD5S3IICUJI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/T3Y7A52TXBEBJNEPGOQSVPQSPU.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/KY33U3WBTNFIBJFMTEF2SM7BOQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JNPS5MGVXJC7BARVMARYQIQHXE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/63N2P6SYAZDURJDO5KARQYX2J4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/C72WX35SXFETTO5OVA2RWT523I.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/F3ER37EV2RGY5CRYFNTWE3JSF4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/L65QCUR32RH2NKCUHXYHHAPDFI.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/VSK246VVRRDMBNQU7B2NTNY6AE.jpg)